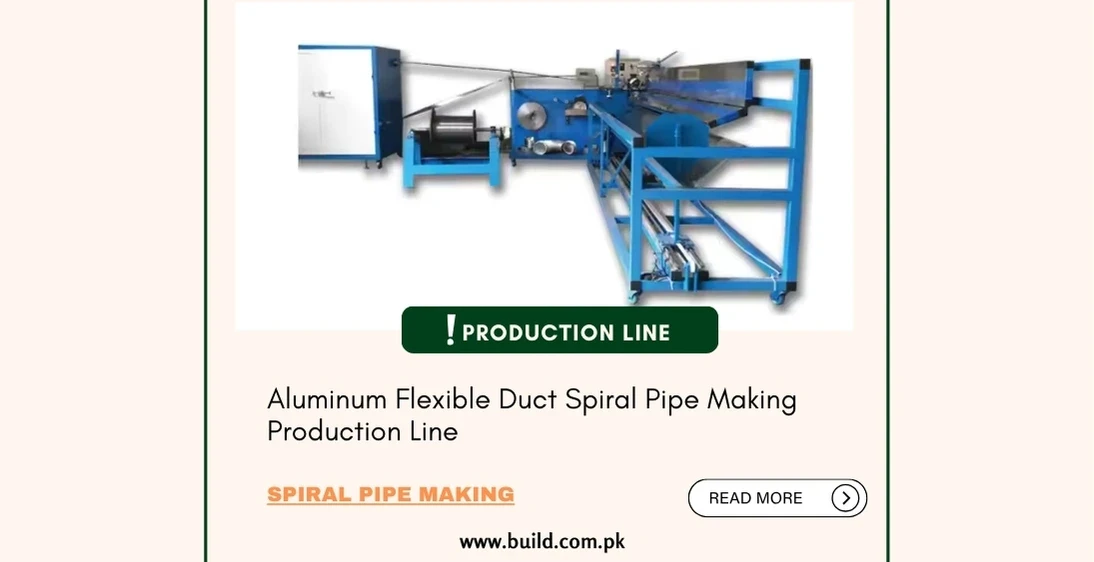

Aluminum Flexible Duct Spiral Pipe Making Production Line

Introduction:

In the world of HVAC systems, the importance of ductwork cannot be overstated. Efficient and properly designed ductwork plays a crucial role in delivering conditioned air throughout buildings. One innovative solution for duct manufacturing is the use of aluminum flexible duct spiral pipe making machines In this blog post, we will explore the intricacies of these machines, their benefits, the process of spiral duct formation, and the impact they have on the HVAC industry.

Understanding Aluminum Flexible Duct Spiral Pipe Making Machines

Aluminum flexible duct spiral pipe making machines are advanced manufacturing tools designed specifically for the production of spiral ductwork. These machines automate the process of forming aluminum ducts into a spiral shape, enhancing efficiency, accuracy, and productivity. By utilizing advanced technology and precise control systems, these machines revolutionize the way spiral ducts are manufactured.

The Process of Spiral Duct Formation

Material Preparation:

The process begins with preparing the aluminum strip, which serves as the raw material for spiral ducts. The strip is typically made of high-quality aluminum alloys known for their durability and corrosion resistance.

Strip Feeding:

The aluminum strip is fed into the spiral duct forming machine. The machine's feeding system ensures smooth and precise movement of the strip, minimizing waste and maximizing material utilization.

Spiral Formation:

The strip passes through various rollers and forming mechanisms, gradually bending and shaping it into a spiral configuration. The machine's advanced control system ensures accurate and consistent spiral formation, resulting in high-quality ductwork.

Seam Locking:

Once the spiral shape is formed, the machine applies a locking mechanism to secure the seams of the duct. This ensures airtight connections and prevents air leakage, optimizing the efficiency of the HVAC system.

Cutting and Length Adjustment:

After the seam locking process, the machine cuts the spiral duct into desired lengths. The length adjustment feature allows for customization based on specific project requirements.

Benefits of having business on Spiral Pipe Making Machines

Enhanced Efficiency:

The automation and precision offered by these machines significantly improve the efficiency of spiral duct manufacturing. They can produce spiral ducts at a faster rate compared to traditional manual methods reducing production time and labor costs.

Consistency and Quality:

Aluminum flexible duct spiral pipe making machines ensure consistent and uniform spiral formation, resulting in high-quality ductwork with precise dimensions. This consistency in manufacturing leads to improved airflow performance and reduced energy consumption in HVAC systems.

Customization and Flexibility:

These machines offer flexibility in terms of spiral diameter, length, and other specifications. This allows manufacturers to produce spiral ducts tailored to the unique requirements of each project, ensuring optimal performance and fit.

Cost Savings:

The automation and efficiency of these machines contribute to cost savings in duct manufacturing. Reduced labor costs, minimized material waste, and increased productivity translate into a more economical production process.

Market Availability

Aluminum flexible duct spiral pipe making machines are available from reputable manufacturers and suppliers in the Build Pakistan. These machines may vary in terms of capacity, features, and customization options. It is essential to research and choose a reliable supplier that offers machines suited to your specific production needs.

Check Out Now: https://build.com.pk/product/aluminum-flexible-duct-spiral-pipe-making-spiral-duct-forming-machine-sr-lbg-358-01

Conclusion: Aluminum flexible duct spiral pipe making machines have redefined the way spiral ducts are manufactured in the HVAC industry. Through automation, precision, and customization capabilities, these machines streamline the production process, leading to cost savings, improved efficiency, and high-quality ductwork. By embracing this innovative technology HVAC professionals can deliver superior airflow performance, energy efficiency, and comfort to buildings of all types and sizes.