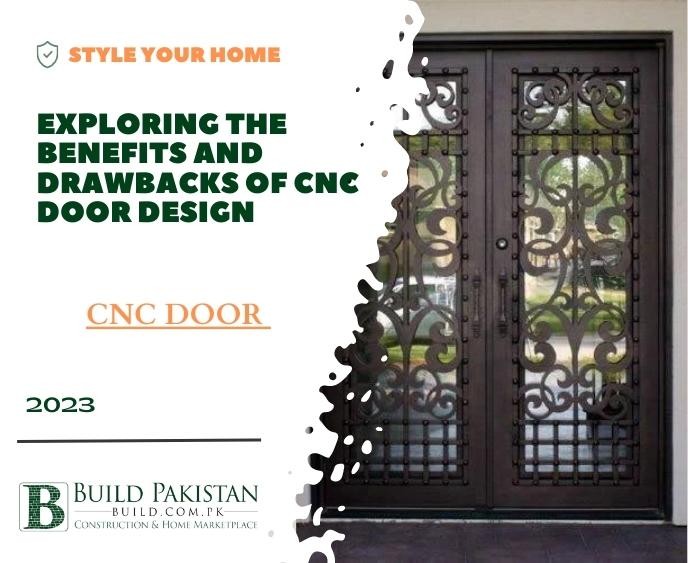

Exploring the Benefits and Drawbacks of CNC Door Design

Introduction:

In the realm of modern architecture and

interior design, advancements in technology continue toreshape the way we

envision and create functional and visually captivating spaces. One such

technological marvel is CNC (Computer Numerical Control) door design. By

utilizing precision cutting and carving techniques, CNC door design has opened

up new possibilities for creating unique and intricate door designs. In this

blog, we will delve into the world of CNC door design, exploring its benefits, drawbacks,

market availability, and notable features.

Understanding CNC Door Design:

CNC door design involves the use of computercontrolled machines equipped with cutting tools to carve out intricate patterns, shapes, and textures on various types of doors. Unlike traditional methods that rely on manual craftsmanship, CNC technology allows for unparalleled precision and consistency in the design process. The computer-guided machines execute precise movements based on digital blueprints, resulting in highly detailed and visually stunning door designs.

Benefits of CNC Door Design

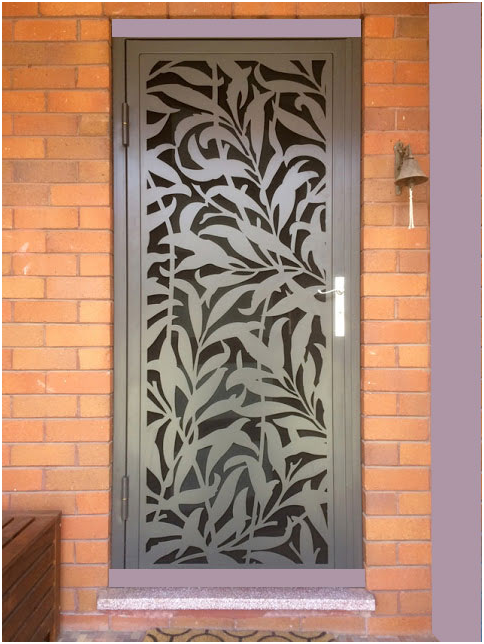

Design Versatility:

CNC technology enables limitless design

possibilities, allowing architects, designers, and homeowners to bring their

creative visions to life. Intricate patterns, geometric shapes, and

personalized motifs can be easily achieved, enhancing the overall aesthetics of

any space.

Precision and Consistency:

CNC machines operate with

remarkable accuracy, ensuring consistent results in each door produced. This

precision is especially valuable when replicating intricate designs or creating

matching sets of doors for larger projects.

Time and Cost Efficiency:

Compared to traditional manual

carving methods, CNC door design significantly reduces production time and

labor costs. The automation of the cutting process streamlines production,

enabling faster turnaround times and greater cost-effectiveness.

Drawbacks of CNC Door Design

Initial Investment:

Implementing CNC technology requires a

substantial initial investment in machinery, software, and training. This cost

can be a barrier for smaller businesses or individuals looking to incorporate

CNC door design into their projects.

Design Limitations:

While CNC machines offer great

flexibility, there may be limitations when it comes to certain design elements.

Extremely intricate or delicate details might not be achievable, and some

materials may not be suitable for CNC cutting.

Market Availability:

CNC door design has gained popularity in

both commercial and residential sectors. Many high-end architectural projects,

luxury residences, hotels, and corporate offices have embraced the unique

appeal of CNC doors. However, the market availaility of CNC doors may vary

depending on your location and the specific suppliers and manufacturers in your

area

Notable Features:

Material Options: CNC doors can be crafted from a wide range

of materials, including wood, metal, glass, and composite materials. This

versatility allows for a seamless integration of CNC door design in various

architectural styles.

Customization Options:

CNC technology empowers clients to

personalize their doors according to their preferences. From choosing specific

patterns, textures, and dimensions to incorporating branding elements or custom

artwork, CNC doors offer endless customzation possibilities.

Conclusion:

CNC door design has ushered in a new era of door

manufacturing, offering unprecedented design versatility and precision. While

there are initial investment costs and limitations to consider, the benefits of

CNC door design, such as design flexibility time efficiency, and consistency,

make it an attractive option for architects, designers, and homeowners alike.

As the technology continues to evolve and become more accessible, CNC doors are

poised to become a defining feature in contemporary architectural projects, adding

a touch of sophistication and uniqueness to any space.