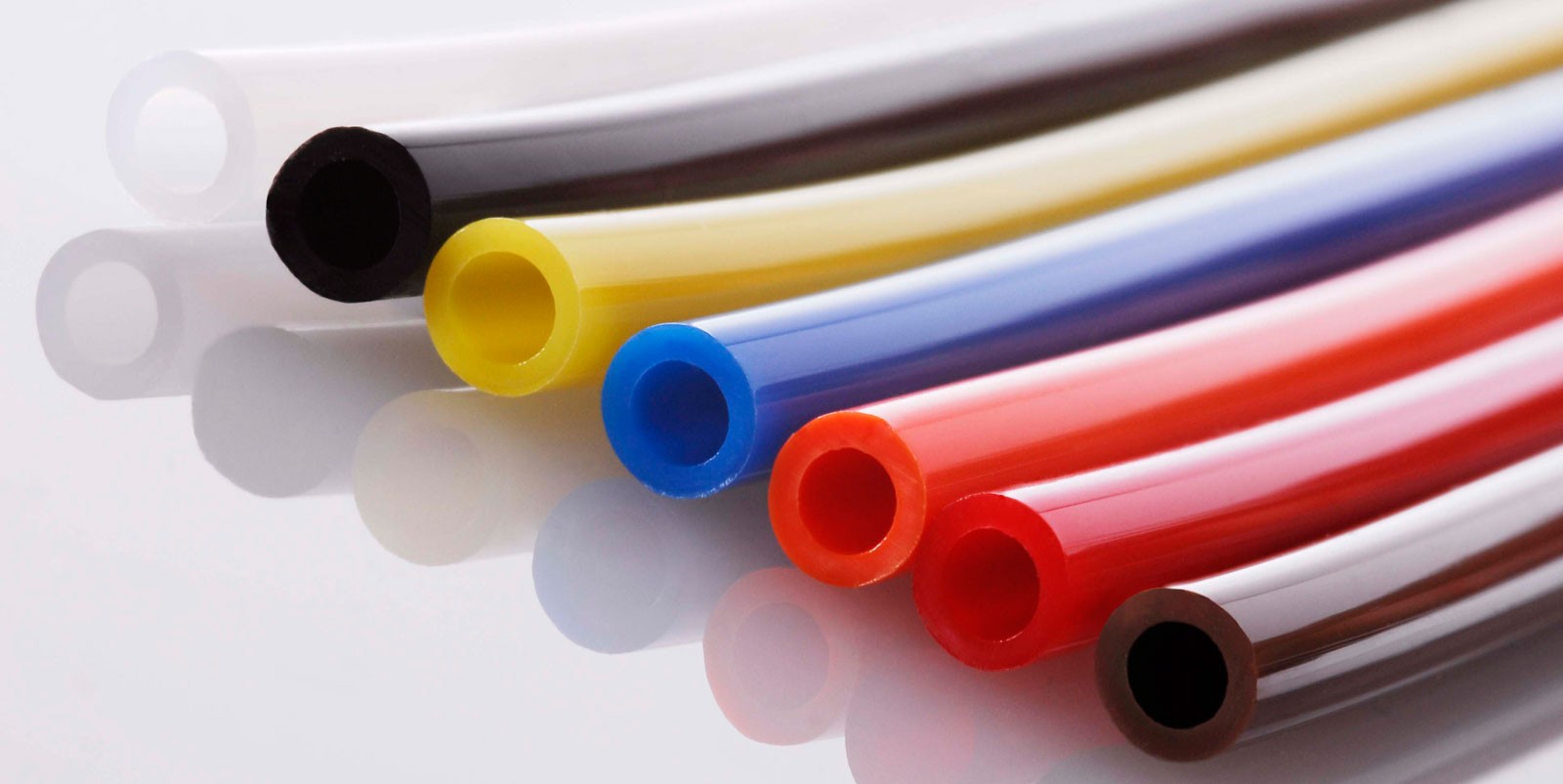

Polyurethane Tubes: An Understanding Guide

Introduction:

Polyurethane

tubes are versatile components used in a wide range of applications due to

their unique properties. Known for their flexibility, durability, and

resistance to abrasion, these tubes are a popular choice in industries ranging

from automotive to medical. This comprehensive uide explores the

characteristics, types, and applications of polyurethane tubes, providing you

with all the information you need to understand and utilize this material

effectively.

What are Polyurethane Tubes?

Polyurethane

tubes are made from polyurethane, a polymer composed of organic units joined by

urethane links. These tubes are known for their exceptional physical

properties, including high elasticity, toughness, and resistance to wear and

tear. Polyurethane can be manufactured in different forms, such as solid, foam,

and elastomeric, making it suitable for various industrial applications.

Characteristics of Polyurethane Tubes

1. Flexibility:

One

of the standout features of polyurethane tubes is their flexibility. These

tubes can bend and stretch without breaking, making them ideal for applications

that require a high degree of maneuverability. This flexibility also makes them

resistant to kinking and cracking, ensuring long-term durability.

2. Durability:

Polyurethane

tubes are incredibly durable, able to withstand harsh environmental conditions

and mechanical stress. They are resistant to abrasion, tearing, and puncturing,

which makes them suitable for heavy-duty applications. Additionally, they

maintain their integrity and performance over extended periods, even under

continuous use.

3. Chemical Resistance:

Polyurethane

tubes exhibit excellent resistance to a variety of chemicals, including oils,

solvents, and fuels. This chemical resistance makes them suitable for use in

environments where exposure to these substances is common. They do not degrade

or weaken when in contact with such chemicals, ensuring reliable performance.

4. Temperature Resistance:

These

tubes can operate effectively across a wide temperature range, typically from

-40°C to 80°C (-40°F to 176°F). This temperature resistance makes them suitable

for both high and low-temperature applications, ensuring consistent performance

regardless of the operating conditons.

5. Lightweight:

Polyurethane

tubes are lightweight, which makes them easy to handle and install. Despite

their light weight, they do not compromise on strength or durability, providing

a robust solution for various applications.

Types of Polyurethane Tubes

Ether-Based Polyurethane Tubes:

Ether-based

polyurethane tubes are known for their excellent hydrolytic stability, making

them ideal for applications involving water and moisture. They are resistant to

fungus and bacteria growth, which is crucial for medical and food processing

applications. These tubes also exhibit good flexibility and durability,

ensuring long-term performance.

Ester-Based Polyurethane Tubes:

Ester-based

polyurethane tubes offer superior resistance to oil, fuel, and other

hydrocarbons, making them suitable for automotive and industrial applications.

They have higher tensile strength and better abrasion resistance compared to

ether-based tubes, making them ideal for heavy-duty applications. However, they

are less resistant to hydrolysis, making them less suitable for water-related

applications.

Reinforced Polyurethane Tubes:

Reinforced

polyurethane tubes are designed for high-pressure applications. These tubes

incorporate a reinforcing layer, such as braided polyester, to enhance their

strength and pressure-handling capabilities. They are ideal for applications

involving hydraulic systems, compressed air, and other high-pressure fluids.

FDA-Approved Polyurethane Tubes:

FDA-approved

polyurethane tubes are designed for use in food, beverage, and medical

applications. These tubes meet the stringent requirements set by the Food and

Drug Administration, ensuring they are safe for contact with food and medical

products. They are resistant to contamination and easy to clean, making them

ideal for hygienic applications.

Applications of Polyurethane Tubes

Automotive Industry:

In

the automotive industry, polyurethane tubes are used in fuel lines, pneumatic

systems, and hydraulic applications. Their resistance to oil, fuel, and high

temperatures makes them suitable for use in engines and other automotive

components. The durability and flexibility of polyurethane tubes ensure they

can withstand the demanding conditions of automotive applications.

Medical Industry:

Polyurethane

tubes are widely used in the medical industry due to their biocompatibility and

resistance to bacterial growth. They are used in medical devices, catheters,

and tubing for fluid transfer. Their flexibility and chemical resistance ensure

safe and reliable performance in medicl applications.

Industrial Applications:

In

industrial settings, polyurethane tubes are used for fluid transfer, pneumatic

systems, and chemical handling. Their resistance to abrasion, chemicals, and

temperature variations makes them suitable for demanding industrial

environments. Reinforced polyurethane tubes are often used in high-pressure

applications, providing reliable performance in hydraulic and pneumatic

systems.

Food and Beverage Industry:

FDA-approved

polyurethane tubes are used in the food and beverage industry for fluid

transfer, dispensing systems, and processing equipment. Their resistance to

contamination and ease of cleaning make them ideal for applications where

hygiene is paramount. They ensure safe and efficient transfer of food and

beverage products.

Agricultural Applications:

In

agriculture, polyurethane tubes are used in irrigation systems, spraying

equipment, and fluid transfer applications. Their durability and resistance to

chemicals and UV radiation make them suitable for outdoor use. They ensure

reliable performance in agricultural operations, contributing to efficient and

effective farming practices.

Marine Applications:

Polyurethane

tubes are used in marine applications for fluid transfer, pneumatic systems,

and protective coverings. Their resistance to saltwater, UV radiation, and

harsh environmental conditions makes them suitable for use in marine

environments. They ensure reliable performance and longevity in demanding

marine applications.

Installation and Maintenance Tips

- Proper Sizing: Ensure you select the appropriate size of polyurethane tube for your application. Consider the inner diameter, outer diameter, and wall thickness to ensure compatibility with your system and the fluids being transferred.

- Secure Connections: Use appropriate fittings and clamps to secure connections and prevent leaks. Ensure the fittings are compatible with polyurethane tubes and provide a tight, secure fit.

- Regular Inspection: Regularly inspect polyurethane tubes for signs of wear, damage, or degradation. Replace any damaged tubes to ensure continuous and reliable performance.

- Avoid Excessive Bending: While polyurethane tubes are flexible, avoid excessive bending or kinking, as this can weaken the material and lead to failure. Use proper routing and support to maintain the integrity of the tubes.

- Clean and Maintain: Regularly clean polyurethane tubes to remove any buildup or contamination. Use appropriate cleaning agents and methods to ensure the tubes remain in good condition.

Conclusion:

Polyurethane tubes offer a versatile and durable solution for a wide range of applications. Their unique properties, such as flexibility, durability, and chemical resistance, make them suitable for use in industries ranging from automotive to medical. By understanding the different types and applications of polyurethane tubes, you can select the best option for your specific needs. Whether you are looking for a robust solution for industrial applications or a safe and relible option for medical use, polyurethane tubes provide a reliable and efficient solution. Embrace the benefits of polyurethane tubes and enhance the performance and longevity of your systems and applications.