Tin Coated Copper Wire: An In-Depth Exploration

Introduction:

Tin

coated copper wire is a specialized type of electrical wire that has a wide

range of applications across various industries. The process involves coating

copper wire with a thin layer of tin to enhance its properties, making it more

resistant to corrosion and easier to solder. This comprehensive guide will

delve into the details of tin coated copper wire, exploring its benefits,

manufacturing process, applications, and much more.

Understanding Tin Coated Copper Wire

What is Tin Coated Copper Wire?

Tin

coated copper wire is essentially a copper wire that has been coated with a

layer of tin through a process called electroplating. This coating serves

multiple purposes, primarily aimed at improving the wire's durability and

performance in different environments.

The Manufacturing Process:

The

manufacturing process of tin coated copper wire involves several steps:

- Wire Drawing: The process begins with drawing the copper wire to the desired diameter. This step is crucial as it determines the thickness and flexibility of the final product.

- Cleaning: The drawn copper wire is thoroughly cleaned to remove any impurities or contaminants that could affect the quality of the tin coating.

- Annealing: The wire is then annealed to soften it, making it more pliable for furter processing.

- Electroplating: The cleaned and annealed copper wire is passed through an electrolytic bath containing tin. An electric current is applied, causing the tin to deposit onto the surface of the copper wire.

- Quality

Control: The coated wire undergoes rigorous quality control checks to ensure

the tin coating is uniform and meets the required standards.

Benefits of Tin Coated Copper Wire

Corrosion Resistance:

One

of the primary benefits of tin coated copper wire is its enhanced resistance to

corrosion. The tin layer acts as a protective barrier, preventing oxidation of

the copper underneath. This makes tin coated copper wire ideal for use in

environments where moisture and other corrosive elements are present.

Improved Solderability:

Tin

coated copper wire is easier to solder compared to bare copper wire. The tin

coating provides a smooth, clean surface that facilitates better adhesion of

solder, resulting in stronger and more reliable connections. This property is

particularly valuable in electronics and electrical applications where precise

and secure soldering is essential.

Enhanced Electrical Conductivity:

While

copper itself is an excellent conductor of electricity, the addition of a tin

coating does not significantly impact its conductivity. In fact, the coating

can improve the overall performance of the wire by reducing contact resistance

and enhancing signal integrity in high-frequency applications.

Longevity and Durability:

The

tin coating not only protects against corrosion but also adds to the overall

durability of the wire. This means that tin coated copper wire has a longer

lifespan and requires less frequent maintenance or replacement, making it a

cost-effective choice for long-term applications.

Applications of Tin Coated Copper Wire

Tin

coated copper wire is used in a variety of industries due to its unique

properties. Some of the key applications include:

Electronics:

In

the electronics industry, tin coated copper wire is widely used for wiring and

connecions in electronic devices and circuit boards. Its excellent

solderability and corrosion resistance make it ideal for these sensitive and

precise applications.

Automotive Industry:

The

automotive industry utilizes tin coated copper wire for various wiring

harnesses and electrical components. The wire's durability and resistance to

harsh environmental conditions make it suitable for use in vehicles, where it

must withstand temperature fluctuations, moisture, and vibrations.

Marine Applications:

Marine

environments are highly corrosive, making tin coated copper wire a preferred

choice for wiring on boats and ships. Its corrosion resistance ensures reliable

performance and longevity even in saltwater conditions.

Telecommunications:

Tin

coated copper wire is also used in the telecommunications industry for various

types of cabling, including coaxial and data cables. Its enhanced conductivity

and signal integrity are crucial for maintaining high-quality communication

links.

Renewable Energy:

In

renewable energy systems, such as solar and wind power installations, tin

coated copper wire is used for electrical connections and wiring. Its

durability and resistance to environmental factors contribute to the efficiency

and reliability of these systems.

Types of Tin Coated Copper Wire

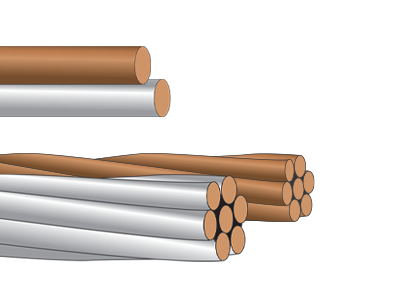

Solid Tin Coated Copper Wire:

Solid

tin coated copper wire consists of a single copper conductor coated with tin.

This type is typically used in applications where a stable and reliable

connection is needed, such as in electronic devices and certain electrical

components.

Stranded Tin Coated Copper Wire:

Stranded

tin coated copper wire is made up of multiple thin copper strands twisted

together and coated with tin. This type of wire offers greater flexibility and

is commonly used in applications where the wire needs to be bent or maneuvered,

such as in automotive and marine wiring.

Choosing the Right Tin Coated Copper Wire

When

selecting tin coated copper wire for your specific application, several factors

need to be considered:

- Gauge: The gauge of the wire determines its thickness and current-carrying capacity. Choosing the right gauge is crucial for ensuring the wire can handle the electrical load without overheating.

- Environment: Consider the environment in which the wire will be used. For harsh environments with high moisture or corrosive elements, ensure the wire has a high-quality tin coating for maximum protection.

- Flexibility: For applications requiring frequent bending or movement of the wire, stranded tin coated copper wire is preferable due to its flexibility and resilience.

- Compliance: Ensure that the tin coated copper wire meets relevant industry standards and regulations for safety and performance. This is particularly important in critical applications such as automotive and aerospace.

Maintenance and Care

Proper

maintenance and care can significantly extend the lifespan of tin coated copper

wire:

- Regular Inspection: Regularly inspect the wire for any signs of wear, corrosion, or damage. Early detection can prevent more significant issues and costly repairs.

- Proper Storage: Store the wire in a cool, dry place to avoid exposure to moisture and other corrosive elements.

- Clean Connections: Ensure all connections are clean and free of debris to maintain optimal conductivity and performance.

- Avoid

Overloading: Do not exceed the wire's rated current-carrying capacity to

prvent overheating and potential damage.

Conclusion:

Tin

coated copper wire is a versatile and reliable solution for a wide range of

electrical and electronic applications. Its unique properties, including

corrosion resistance, improved solderability, and enhanced durability, make it

an ideal choice for industries such as electronics, automotive, marine,

telecommunications, and renewable energy. By understanding the benefits,

applications, and considerations associated with tin coated copper wire, you

cn make informed decisions for your specific needs and ensure long-lasting and

efficient performance.